Mud, Model T Fords and an Erie Type ‘A’

By William R. Dancey

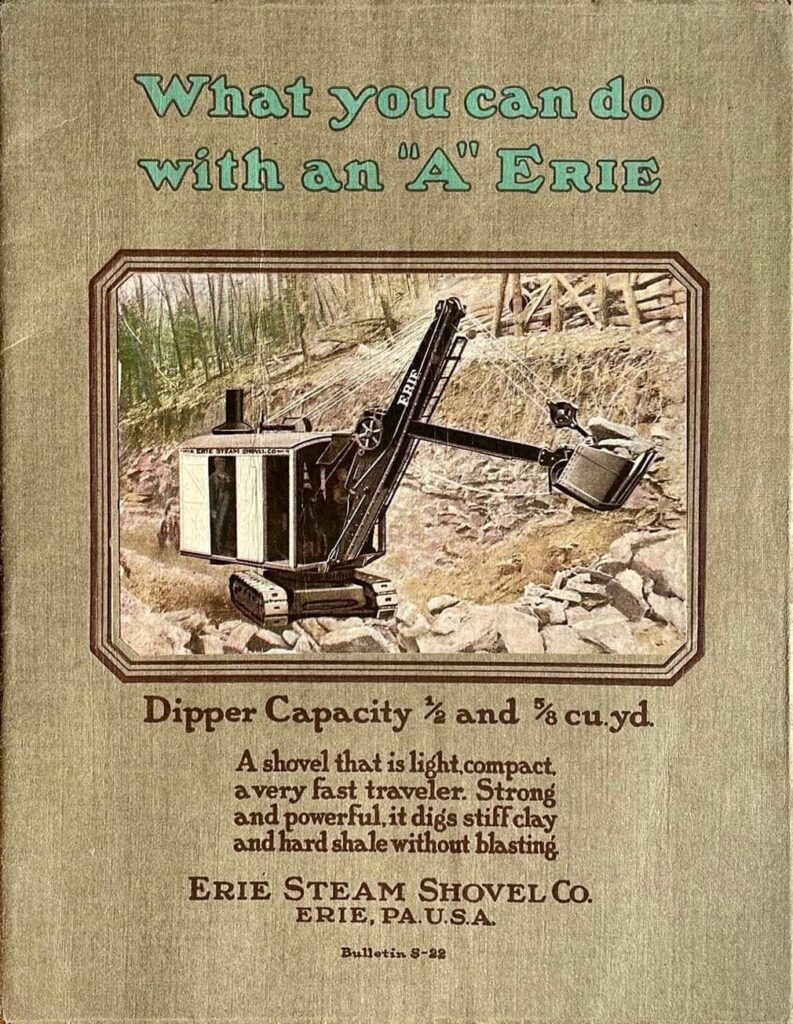

~ Erie Type A Mechanical Specifications ~

- Year Built: 1925

- Serial Number: 3272

- Weight: 13 Tons

- Fuel: Soft Coal

- Boiler Pressure: 150 PSI

- Crew: Fireman, Engineer & Groundsman

- Bucket Capacity: ½ Cubic Yard

- Earth-Moving Rate: 300 Cubic Yards per Day

America Takes to the Road:

It really wasn’t so long ago, but life in the United States used to be very different than it is today. With the Great War still fresh in peoples minds and the new Volstead Act ratified into law, the Roaring Twenties began as a period of intense technological and social change. Transatlantic flight had just been proven possible but colossal greyhound ocean liners still ruled the seas. Ragtime had completed its evolution into jazz, and this first real ‘popular music’ could be heard loudly in cities across the country – or faintly behind the closed doors of a speakeasy. Less than half of the countries homes were electrified. Automobiles still shared the streets with horse-drawn buggies, and roadways everywhere were in a horrible state!

When horseless carriages first began to sputter up and down American highways, travel was oftentimes an arduous undertaking. The slow, uncomfortable horse-drawn carriages of those days ensured that most people would never travel more than a dozen miles or so from their birthplace. Not only was the transportation itself slow and unpleasant, but earthen roads became a muddy quagmire with even the slightest amount of rain. Early motorists were faced with the prospect of traversing these rutted and swampy trails – the remark “Get a Horse” was frequently directed at automobile owners who found themselves in a predicament. For those who could afford it, though, motoring was a faster and more pleasant way to travel when compared with the alternative. The idea stuck, despite early drawbacks and shortcomings. Cars were in America to stay, and the Automobile Age had begun.

Catering to the exceptionally wealthy with his early line of motor cars, the middle-aged farmer turned engineer Henry Ford sought to make automobiles attainable for the masses. What resulted is arguably the most successful and prolific set of wheels ever devised – the Ford Model T. With a sticker price of $825 at the time of their debut in 1908, these simple but robust vehicles became an instant sensation due in large part to their low purchasing cost. After some refinements and with the perfection of his assembly line, Ford was able to slash prices further and by 1925 you could buy a Model T for only $260 (a mere $4,500 in 2023)! As promised, Ford had built a car so affordable that any man could own one. Motor mania was now in full swing, and as people began flocking en-masse to the highways one thing became increasingly apparent – roads in the United States were in desperate need of improving. To do this improving, though, some heavy machinery and a whole lot of material would be required.

Strangers on a Train:

Fred McBrier above all else was a businessman. While traveling by rail just over a century ago, he was pondering a serious problem. As Vice President of his families concern – the Ball Engine Company of Erie, Pennsylvania – McBrier was proud of the reputation he had garnered for building some of the finest stationary steam engines on the market. Supplying power for heavy industries such as mining, forestry, factories and mills around the world was sensationally profitable. Being the astute businessman he was, though, McBrier could see writing on the wall. He recognized a slow but inevitable shift away from steam power in heavy industry and knew his company could be in serious trouble. A new line of equipment for Ball to produce needed to be found, but the question as to what type of equipment remained unanswered.

Enter the exuberant young salesman A.C. Vicary – representative of the Thew Automatic Shovel Company based in Lorain, Ohio. A wizard solicitor, Vicary had been selling power shovels for years and knew firsthand the many challenges that shovel operators and their machines were up against. This caused the forward-thinking salesman to develop some unique perspectives on both shovel design and the best ways to sell them. When McBrier and Vicary just happened to board and cross paths on the same passenger train, it is said the duo got along like a house on fire! They began to envision a line of steam shovels which were versatile, user-friendly and standardized in design to allow for quick assembly and repair. McBrier had found his new line of equipment, and Vicary an opportunity to produce what he saw as the ideal steam shovel. Before long, Vicary had joined the ranks of Ball and began his mission in earnest.

What culminated was the start of a famously successful line of power shovel, which Ball chose to brand after its home town. Erie shovels had come into being and would soon grow into the industry standard for small excavators. At first only two models were offered, and strangely enough the 20-ton Type B predated the 13-ton Type A by a year with B’s first being offered in 1915 and A’s following in 1916. Ball made the decision to completely sell its line of stationary engines in 1920, and shortly afterwards in 1922 changed their corporate name to the Erie Steam Shovel Company which better fit their champion product. In addition to the A and B, Erie went on to produce a Type B-2 ‘Dreadnaught’ and GA-2 (gas + air) shovel before merging with Bucyrus in 1928 at the height of their success. When an ordinary Type A with serial number 3272 left the factory in 1925, it joined thousands of peers already in operation around the globe.

Perfect Machine for the Job:

Being a far cry from those behemoth shovels which dug the Panama Canal, an Erie Type A was by comparison positively diminutive. Out of all the machines Erie produced, the ‘A’ was smallest – in fact, it was one of the smallest power shovels ever manufactured and would have looked out of place on most construction projects taking place in the early 20th century. Serving a much more humble purpose, Type A’s were intended to be the first step in a nationwide progression away from hand labor for everyday construction companies, municipalities and mine operators. It was once claimed by such an operator that, “We stripped more rock in five days with our Erie A than we accomplished previously in six weeks with eight men and four carts!” Such a claim shows that an Erie A was exceptionally well-suited to such work, and so remained in production well after the Bucyrus merger of 1928.

It should come as no surprise, then, that such an outstanding reputation coupled with the countries insatiable appetite for road construction materials during the mid-20’s led to Type A #3272 being ordered, built and shipped west from Pennsylvania to the far-flung suburbs of Chicago in 1925. Soon taking up residence at a small family operated quarry deep in the Illinois countryside north of Rochelle, IL our Type A was put to work. Overall the job was simple – after drilling into a rock wall and setting dynamite charges, the quarrymen would retreat a safe distance to detonate their explosives. What resulted was a massive amount of material being jarred loose and settling into piles at the quarries base. As the dust cleared, our shovel would be steamed over to these newly created heaps of rubble along with a belt-driven rock crusher. Scoop after scoop, our Erie kept its companion rock crusher fed as both labored to produce vast quantities of gravel. When the debris had been cleared, these machines were moved away and the whole process repeated.

An untold amount of gravel left the pit at Rochelle, and is undoubtedly present in much of the surrounding areas infrastructure even to this day. Our Type A played a part in expanding the nations system of paved roads, and did so without complaint for many years. Even with the advent of more contemporary power sources, steam remained the driving force in the small Rochelle quarry. New equipment was expensive, and the little shovel was good at its job. Interesting to note that even when our Erie was new in 1925, steam power was already considered obsolete! The reason #3272 was built with a steam plant at all is also the same reason it remained in operation for so long; people were simply more familiar and comfortable with the antiquated power source. The technology was simple and repairs oftentimes much easier to perform than those of internal combustion engines. It was only when the quarry at Rochelle became petered out that the end finally came. Our shovel had worked into the 1960’s, and was ultimately left to rest in the now inactive pit.

When talk began about filling the old quarry in, our shovels fate looked to be sealed. Like so many of its peers, the venerable Erie would simply be buried and forgotten. That is, unless the sentimental owners of the shovel had anything to say about it! The Fruit family enjoyed old machinery, and even though many at the time would have considered it to be nothing more than useless scrap metal they wanted to keep their machine. Brought out of the pit, our shovel was taken to storage near Franklin Grove, IL. Occasionally fired up for small parties or groups of steam and tractor enthusiasts, George Fruit enjoyed giving his dog rides in the Erie’s bucket – much to the delight of both the animal and onlookers! These get-togethers, though, didn’t last forever and the stalwart old machine sat dormant for many years in the dark barn near Franklin Grove.

One of a Kind:

Formed in 1956, the Northern Illinois Steam Power Club (NISPC) was about to reach a major milestone. Come 2006, they were going to be hosting their 50th annual Threshing Bee outside of Sycamore, IL and wanted to make it a reunion worth remembering. ‘Why not try to bring in a steam traction engine for every year of the clubs existence,’ thought the Directors! A search was begun – rounding up such massive quantities of old iron was (and still is) no small feat in todays age of preservation. It occurred to someone that even though Fruits old shovel was no steam tractor it could still be a fascinating exhibit at the show.

With such a fantastic excuse to bring it out of hiding, a truck was sent to Franklin Grove and our Erie emerged into the limelight. After some minor repairs and testing, the shovel proved healthy as ever and came back to life with vigor! Having lost its original wooden housing to a fire sometime after WWII, the machines inner-workings were clearly visible for fascinated crowds of onlookers to observe. Indeed, the words of Virginia Lee Burton’s 1939 storybook ‘Mike Mulligan and His Steam Shovel’ were proving to be true. The more folks that stopped to watch, our old Erie (now dubbed Mary Anne) would dig a little bit faster and a little bit better! Everyone knew that Mary Anne was special, and exceptionally rare. Just how rare, though, would not become immediately clear.

Mary Anne had been a smash hit at the 2006 reunion, and the Fruits decided to make NISPC’s showgrounds her new permanent home. They were more than happy to exhibit such an extraordinary machine, and even reconstructed the old wooden house using vintage photographs. Cobwebs were continually knocked off, some more small repairs completed and soon Mary Anne had no trouble making dirt fly just as she did back in the Roaring Twenties! It became apparent that Mary Anne – which everyone already knew was rare – turned out to be exceptionally rare. Unlike so many of her peers, Mary Anne had escaped the fate of being buried, sunken or scrapped. Years of painstaking research has shown that she is one of only five (and ½) Erie Type A’s known to exist. Surely there are others, but it is unlikely they will ever be saved from their resting places. Mary Anne is truly the last of a very rare breed and her survival nothing short of miraculous.

Eventually, the Fruit family deemed NISPC to be worthy stewards of their treasured machine and passed its custody along to them in 2018 – an ongoing effort to recondition Mary Anne has been taking place since then. Although still in good mechanical shape, she has never received a comprehensive restoration since leaving the factory nearly a century ago. Current efforts are underway to construct a brand new and historically accurate boiler as well as replacing some corroded steel beams around the frame. Replacing a boiler does not come lightly, but doing so ensures that the dirt at Sycamore can continue to fly for many decades to come! As you tour the showgrounds, be sure to stop by and see her – and remember that a big crowd means Mary Anne will dig a little bit faster and a little bit better!

Preservation Is a Journey, Not a Destination

By Grace Druien, With Materials Provided by Jacob Stuffle

When the NISPC purchased Mary Anne they did so knowing that preserving such a unique piece of steam history wsa going to be quite an undertaking. Just like any other Steam Engine, maintenance never stops.

Immediately after the 2022 show Mary Anne was carefully taken apart. Her boiler was removed and loaded onto a truck to be taken to Wheatland Machine and Repair so that it could be throughly inspected. Removing the boiler also allowed for a closer inspection of of the frame underneath the wooden cabin, revealing that much of the floor, and the steel beams underneath were corodded and would also likely need to be replaced.

Wheatland Machine and Repair performed both a visual and UT inspection of the nearly 100 year old boiler, and returned their findings to the NISPC. After exploring many different repair options, it was ultimately decided to fully replace the boiler with a brand new one.

Mary Anne’s boiler has been taken to Canada, where at the time of writing this, it is currently waiting to be used as a pattern for the new boiler.